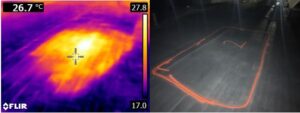

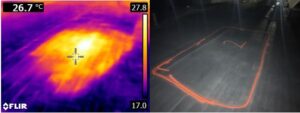

What is an infrared roof moisture survey?

An infrared roof moisture survey is a non-destructive diagnostic technique used to identify and evaluate moisture within a building’s roofing materials. This process utilizes the

Are you looking for a reliable Electronic Leak Detection (ELD) company near you? Atlantic Testing Services is a dependable leak detection company providing high-quality electronic leak detection services that help building owners identify the root cause of the problem to guarantee a fast solution. We utilize the latest technology for non-destructive leak testing, infrared thermography and utility locating. We are located in Marlboro, NJ, Woburn, MA and NYC and serve the entire USA.

We are more than a simple water leak detection company with locations in Woburn, MA, Marlboro, NJ, and NYC. We provide a full line of infrared services, electronic leak detection (ELD), and private utility locating / concrete scanning to ensure you can find everything you need, whether starting a construction project, requiring repairs or in need of a full analysis.

“Our commitment is to provide exceptional services that enable solutions, savings and safety for our clients.

Our traditional values and modern technology are the foundation of our company mission as an industry leader.”

For more than a decade, we've only employed expert certified technicians.

Technology is always changing and we know how important it is to stay up-to-date.

We pride ourselves on being reliable, trustworthy, and professional.

We operate under the standards set forth by world leading organizations.

We’ve located over 52,000 leaks, tested millions of SF of waterproofing and located thousands of miles of buried utilities.

Safety for our clients, our employees, and our neighbors is our highest priority.

An infrared roof moisture survey is a non-destructive diagnostic technique used to identify and evaluate moisture within a building’s roofing materials. This process utilizes the

I have always been a big proponent of “Friendly Competition” amongst businesses in the same industry or field. I’ve researched the benefits of friendly competition

Early detection of electrical problems: Infrared inspections can identify potential electrical faults before they cause unscheduled downtime or safety hazards. By identifying issues before they

The National Fire Protection Association and most major insurance underwriters recommend completing electrical infrared testing annually to protect your property and guard against electrical issues that can cause a costly fire.