As a business owner, you know better than anyone that the equipment in your building is expensive and critical to your company’s success. Whether you just have standard HVAC and electrical components or additional electrical equipment, knowing when you’re at risk of unscheduled downtime or catastrophic failure, can save you time, money, and frustration.

Below, we discuss what infrared electrical inspections are and how they can help you and your company save money.

What Are Infrared Electrical Inspections?

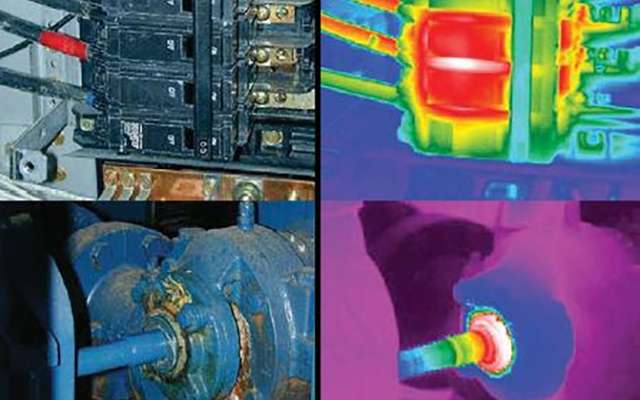

Infrared (IR) electrical inspections can be done on almost any piece of electrical equipment. It is non-invasive, non-destructive and uses IR technology to find areas that may be at risk of failure. Infrared Thermography is used to inspect everything from typical electrical circuitry to specialized electrical devices, from simple electrical breaker panels to entire electrical distribution and sub-stations.

What Do They Test?

All electrical equipment produces heat when running, but malfunctioning components or those that aren’t working as efficiently as they should give off excess heat. IR scanning is a fast and reliable way to see heat differentials in your devices and detect early signs of equipment failure.

How They Save You Money

Every business owner is concerned about their bottom line, so below are the four ways these inspections can save you and your company money.

1 – Reduce Equipment Damage

With IR testing, you’ll get a visual of any internal components that may be at risk of failure. This information allows you to make preventative repairs to minimize equipment damage and unscheduled downtime if something does go wrong.

2 – Reduce Risk of Fire

Electrical components that aren’t working correctly can easily cause fires in your building. IR testing will expose those components, and you can repair them before they become more likely to cause a fire that could damage your property, injure your employees, and put your business on hold.

3 – Increase Effectiveness of Maintenance Personnel

The professionals you hire to maintain your electrical devices and systems may be world-class, but they will only be able to fix and repair the damage they can see. IR electrical inspections reveal internal component damage that could lead your maintenance personnel to carry out the most cost-effective solutions and repairs.

4 – Improve Quality Control

Not only will your systems run more safely with IR electrical inspections, but they’ll also operate more efficiently. With improved production rates and accuracy, your quality control will likely be better than ever after IR inspections and repairs.

Infrared electrical inspections offer an affordable and non-invasive look into the electrical equipment in your building. They can guide cost-effective and preventative repairs that could prevent fire damage, equipment damage, and negative impacts on your day-to-day business. When you’re ready to have your equipment inspected, contact one of our highly trained technicians to set up a consultation.