An annual Infrared Electrical Inspection can help protect your facility in several ways:

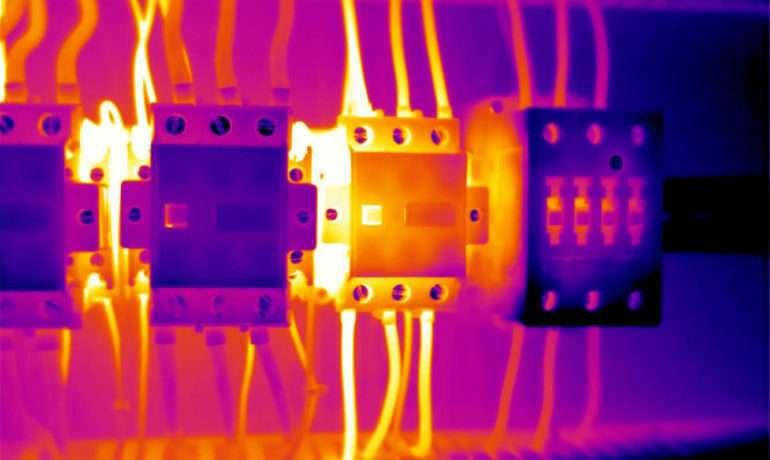

- Early detection of electrical issues: Infrared electrical inspections involve using specialized infrared cameras to detect heat patterns and anomalies in electrical systems. This allows you to identify electrical components that are operating at higher temperatures than normal. By detecting these hotspots early, you can address potential issues before they escalate into serious problems such as electrical failures, equipment damage, or even fire hazards. Early detection helps prevent unplanned downtime and reduces the risk of costly repairs or replacements.

- Preventive maintenance planning: By conducting regular infrared inspections, you can establish a baseline for the normal operating temperatures of your electrical equipment. Over time, you can track any changes or deviations from this baseline, which can indicate developing issues. With this information, you can proactively plan maintenance activities and address potential problems during scheduled downtime, minimizing the impact on your facility’s operations.

- Increased electrical system reliability: Electrical systems that are subject to regular infrared inspections are more likely to operate reliably. By identifying and rectifying potential issues early on, you can prevent unexpected failures and outages. This helps maintain the continuity of your facility’s operations and reduces the risk of costly downtime.

- Enhanced safety: Electrical issues, such as loose connections, overloaded circuits, or faulty equipment, can pose significant safety hazards. By detecting these issues through infrared inspections, you can take corrective measures to eliminate or minimize the risks. This contributes to a safer working environment for your employees, reduces the likelihood of electrical accidents, and helps you comply with safety regulations.

- Energy efficiency optimization: Infrared inspections can also identify energy inefficiencies within electrical systems. For example, overheating components may indicate excessive electrical resistance, which leads to energy losses. By addressing these inefficiencies, you can optimize energy usage, reduce utility costs, and contribute to your facility’s overall sustainability efforts.

Overall, an annual infrared electrical inspection provides a proactive approach to facility maintenance, helping to identify potential electrical issues before they result in failures or safety hazards. By taking preventive measures and addressing concerns early on, you can protect your facility, improve operational reliability, and minimize the risk of unplanned downtime and costly repairs.

Call Atlantic today at (888) 696-6429 for more information.